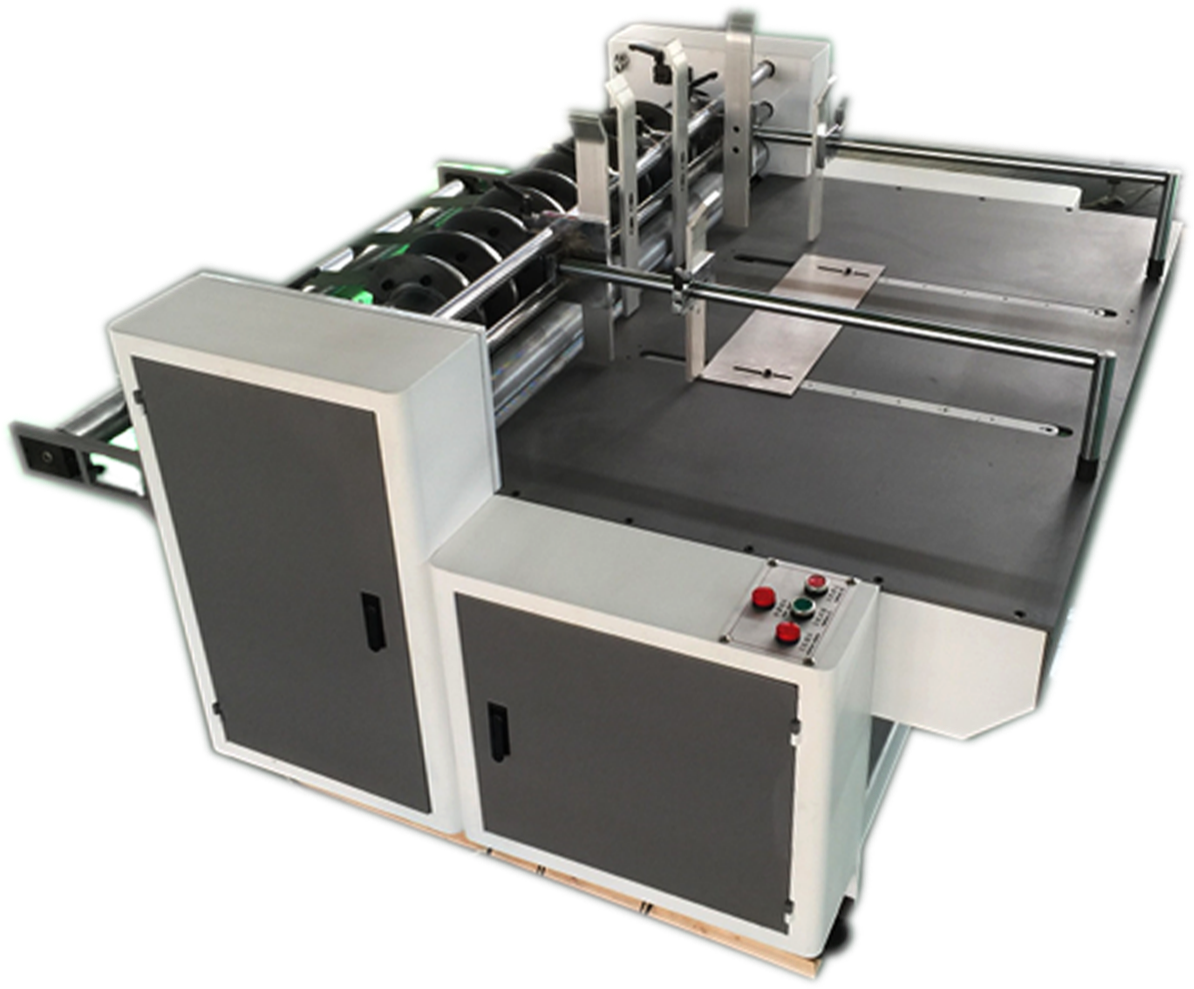

In the manufacturing world, precision and efficiency are paramount, especially when working with materials like partitions, panels, and other structural components. One of the key machines that help achieve both of these goals is the partition slotting machine. These machines are specifically designed to create precise slots in partitions, panels, and other components, ensuring that the final product fits together seamlessly in a wide range of industrial applications. This article will explore the features, benefits, and advantages of partition slotting machines, and how they can significantly enhance productivity in your manufacturing processes.

A partition slotting machine is an industrial tool used for making slots in materials such as wood, metal, plastic, and other partition materials. The machine works by using a slotting tool to cut narrow, precise grooves or slots into the material. These slots are often necessary for assembly, where multiple components must be joined together, or for structural purposes, where the slot is required for fittings, connectors, or other parts.

Slotting machines are typically powered by either manual or automated systems, with modern versions often incorporating CNC (Computer Numerical Control) technology for enhanced precision and control. This makes the partition slotting machine highly effective for tasks requiring consistent, repeatable results.

One of the most significant advantages of the partition slotting machine is its ability to produce slots with high precision. The machine’s advanced mechanics and fine-tuned settings allow for consistent slot depths and widths, ensuring that each partition meets the exact specifications required for a perfect fit in the final product.

Partition slotting machines are versatile tools that can be used on a variety of materials, including:

Wood: Often used in furniture or partition wall construction.

Metal: Essential for industrial applications where metal panels or sheets need to be slotted.

Plastic: Used for creating slots in plastic sheets for partitions or casings.

This flexibility makes the partition slotting machine an essential tool across several industries, from construction to furniture manufacturing.

Many modern partition slotting machines are equipped with CNC technology, which allows for automatic adjustments to the slotting process. CNC machines can perform highly complex tasks with minimal human input, resulting in greater efficiency, fewer errors, and more precise results. Operators can program the machine for specific slot sizes and depths, optimizing the process for different materials.

Some advanced machines offer the ability to create multiple slots at once, reducing production time. The machine can be programmed to create multiple grooves along the length of a partition or panel, which increases overall productivity.

A key benefit of modern partition slotting machines is their customizable settings. These machines allow operators to adjust the depth, width, and alignment of the slots according to the specific requirements of the job. This ensures that the final product fits seamlessly into the desired application.

Using a partition slotting machine boosts manufacturing efficiency. By automating the slotting process, production time is drastically reduced. Automated and CNC-powered machines also require less manual intervention, allowing workers to focus on other tasks, leading to greater overall productivity in the workshop or factory.

Manual slotting processes can be prone to human error, leading to inconsistencies or wasted materials. Partition slotting machines eliminate much of this risk, as the machines follow preset instructions with high accuracy, ensuring that each slot is cut with precision.

While purchasing a slotting machine may be an investment upfront, it pays off in the long run. The automation and precision of the machine reduce the need for costly mistakes and rework. In addition, the increased speed of production allows for greater output, making it a cost-effective choice for large-scale manufacturing.

The consistency offered by partition slotting machines is another major benefit. Whether you’re slotting hundreds or thousands of partitions, each one will have the same level of accuracy, which is vital in industries where precision is critical.

Partition slotting machines are widely used in various industries for different applications. Some of the most common uses include:

Furniture Manufacturing: Slotting machines are used to create slots in wood or MDF panels, which are necessary for assembling furniture like cabinets, tables, and partitions.

Construction and Partition Wall Assembly: In the construction industry, these machines are used to slot metal or wooden panels that are part of the structure of partition walls or modular systems.

Automotive and Aerospace: Partition slotting machines are also employed in industries like automotive and aerospace, where precise slotting in panels is needed for fittings and assembly.

Plastic Products: For manufacturers who deal with plastic products, the partition slotting machine is often used to create precise slots in plastic sheets that will be used for partitions, displays, or packaging.

When selecting a partition slotting machine, it’s essential to consider factors such as the material you’ll be working with, the size of the partitions or panels, and the required precision. You should also think about the machine’s automation level and whether it uses CNC technology, as this will impact both the cost and the overall efficiency of the machine.

Other important factors include the machine’s slotting capacity, the type of slots it can create (e.g., single, multiple), and any additional features such as adjustable slot sizes, ease of maintenance, and operator safety features.